A mechanical stage cement collar is a type of casing attachment used in oil and gas drilling operations. It is designed to provide a seal between the cement sheath and the casing to prevent fluid migration and to provide additional mechanical support to the casing.

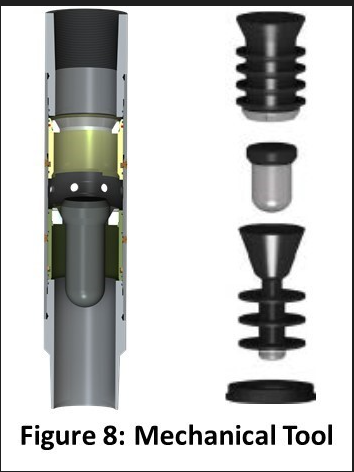

The mechanical stage cement collar is typically installed at a predetermined depth in the wellbore, below the surface casing shoe and above the production casing shoe. It consists of a specially designed collar with a number of mechanical devices such as slips, packers, and hydraulic setting tools, which enable it to anchor the casing firmly in place and provide a barrier against fluid migration.

The primary purpose of the mechanical stage cement collar is to ensure that the cement sheath adheres to the casing and forms a reliable barrier to prevent fluid migration in the wellbore. This helps to maintain well integrity and prevent contamination of the surrounding environment. Additionally, the mechanical stage cement collar provides additional mechanical support to the casing, which can help to prevent casing failure due to high pressures or other stresses.

Overall, the mechanical stage cement collar is an important component of the wellbore construction process in oil and gas drilling operations, and is critical to ensuring the safe and efficient extraction of hydrocarbons from the earth.

Types Of Mechanical Stage Cement Collars

There are several types of mechanical stage cement collars used in oil and gas drilling operations. Here are a few examples:

Slip-on collar

This type of collar is designed to slip over the casing and be held in place by slips, which are mechanical devices that grip the casing. The slip-on collar is typically used in shallow wellbores where the cement sheath is not exposed to high pressures.

Hydraulic-set collar

This type of collar is set in place using hydraulic pressure, which activates a series of mechanical devices such as slips and packers. Hydraulic-set collars are typically used in deeper wellbores where the cement sheath is exposed to higher pressures.

Drillable collar

This type of collar is designed to be drilled out after the cement has set, allowing the casing to be easily removed if necessary. Drillable collars are typically used in wellbores where the casing may need to be removed or replaced.

Composite collar

This type of collar is made from composite materials such as carbon fiber or fiberglass, which provide high strength and resistance to corrosion. Composite collars are typically used in corrosive environments or in wells where high temperatures or pressures are expected.

Inflatable collar

This type of collar is designed to be inflated using a hydraulic pump or other device, which expands the collar and creates a tight seal against the casing. Inflatable collars are typically used in situations where a tight seal is required, such as when drilling through highly permeable formations.

These are just a few examples of the types of mechanical stage cement collars that are used in oil and gas drilling operations. The specific type of collar used will depend on a number of factors, including the depth and pressure of the wellbore, the type of formation being drilled, and the specific requirements of the drilling operation.